DISPERSIBILITY OF NANOCRYSTALLINE CELLULOSE IN ORGANIC SOLVENTS

DOI:

https://doi.org/10.14258/jcprm.2019014240Keywords:

nanocrystalline cellulose, re-dispersibility, particle sizeAbstract

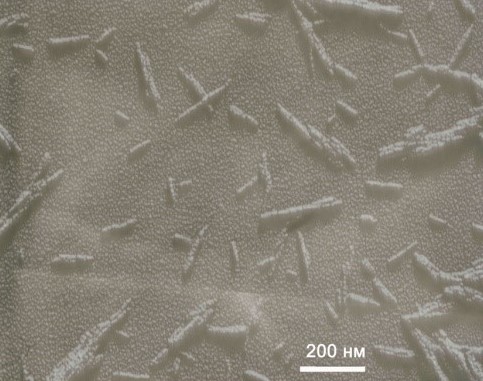

Aqueous suspensions of nanocrystalline cellulose (NCC) were obtained by sulfuric acid hydrolysis using the standard procedure. Suspensions, films and airgel of NCC were characterized by various methods: the degree of polymerization was determined, elemental analysis was carried out, the degree of crystallinity and crystallite size were calculated on the basis of X-ray data, the morphology of NCC aerogels was studied using scanning electron microscopy. The particle size of the NCC was determined using a transmission electron microscope, a scanning atomic-force microscope and the method of dynamic light scattering. NFC hydrosols with different pH were used to prepare lyophilized NCC samples. From NCC hydrosols with pH 2.2, by gradual replacement of water with an organic solvent, NCC organogels with acetone, acetonitrile and ethanol were obtained.

The process of dispersion of lyophilized NCC and NCC organogels (acetone, acetonitrile and ethanol) in water and in 11 organic solvents was investigated. The effect of the pH of the initial aqueous suspension of the NCC and the solvent forming the NCC organogel on the repeated dispersibility of the NCC is shown. The optimum pH value of the initial aqueous suspension of NCC was determined, which determines the maximum dispersibility of the lyophilized samples in each specific solvent. It was shown that dispersion of acetone, acetonitrile and ethanol organogels in most of the solvents studied occurs with the formation of particles less than 100 nm.

Downloads

References

2. Eichhorn S.J. Soft Matter., 2011, no. 7, pp. 303–315, DOI: 10.1039/c0sm00142b.

3. Deepa B., Abraham E., Cordeiro N., Mozetic M., Mathew A.P., Oksman K. et al. Cellulose, 2015, vol. 22, pp. 1075–1085, DOI: 10.1007/s10570-015-0554-x.

4. Habibi Y., Lucia L.A., Rojas O.J. Chem. Rev., 2010, vol. 110, pp. 3479–3500, DOI: 10.1021/cr900339w.

5. Eichhorn S.J., Dufresne A., Aranguren M., Marcovich N.E., Capadona J.R., Rowan S.J., Weder C., Thielemans W., Roman M., Renneckar S., Gindl W., Veigel S., Keckes J., Yano H., Abe K., Nogi M., Nakagaito A.N., Mangalam A., Simonsen J., Benight A.S., Bismarck A., Berglund L.A., Peijs T. J. Mater Sci., 2010, vol. 45, no. 1, pp. 1–33, DOI: 10.1007/s10853-009-3874-0.

6. Cao X., Dong H., Li C.M. Biomacromolecules, 2007, no. 8, pp. 899–904, DOI: 10.1021/bm0610368.

7. Bondeson D., Mathew A., Oksman K. Cellulose, 2006, vol. 13, no. 2, pp. 171–180, DOI: 10.1007/s10570-006-9061-4.

8. Araki J., Wada M., Kuga S., Okano T. Colloids Surf. A., 1998, vol. 142, pp. 75–82, DOI: 10.1016/S0927-7757(98)00404-X.

9. Liu D., Zhong T., Chang P.R., Li K., Wu Q. Bioresour Technol., 2010, vol. 101, no. 7, pp. 2529–2536, DOI: 10.1016/j.biortech.2009.11.058.

10. Espinosa S.C., Kuhnt T., Foster E.J., Weder C. Biomacromolecules, 2013, vol. 14, no. 4, pp. 1223–1230, DOI: 10.1021/bm400219u.

11. Um B.H., Karim M.N., Henk L.L. Appl. Biochem. Biotechnol., 2003, vol. 105–108, no. 1–3, pp. 115–125, DOI: 10.1385/ABAB:105:1-3:115.

12. Yan C.-F., Yu H.-Y., Yao J.-M. Cellulose, 2015, vol. 22, no. 6, pp. 3773–3788, DOI: 10.1007/s10570-015-0761-5.

13. Chen L., Zhu J.Y., Baez C., Kitin P., Elder T. Green Chem., 2016, vol. 18, pp. 3835–3843, DOI: 10.1039/C6GC00687F.

14. Espino-Perez E., Domenek S., Belgacem N., Sillard C., Bras J. Biomacromolecules, 2014, vol. 15, no. 12, pp. 4551–4560. DOI: 10.1021/bm5013458.

15. Spinella S., Maiorana A., Qian Q., Dawson N.J., Hepworth V., McCallum S.A., Ganesh M., Singer K.D., Gross R.A. ACS Sustain Chem. Eng., 2016, vol. 4, no. 3, pp. 1538–1550, DOI: 10.1021/acssuschemeng.5b01489.

16. Braun B., Dorgan J.R. Biomacromolecules, 2008, vol. 10, no. 2, pp. 334–341, DOI: 10.1021/bm8011117.

17. Cheng M., Qin Z., Chen Y., Liu J., Ren Z. Cellulose, 2017, vol. 24, pp. 3243–3254, DOI: 10.1007/s10570-017-1339-1.

18. Siqueira G., Tapin-Lingua S., Bras J., da Silva Perez D., Dufresne A. Cellulose, 2010, vol. 17, no. 6, pp. 1147–1158, DOI: 10.1007/s10570-010-9449-z.

19. Filson P.B., Dawson-Andoh B., Schwegler-Berry D. Green Chem., 2009, vol. 11, pp. 1808–1814, DOI: 10.1039/b915746h.

20. Torlopov M.A., Udoratina E.V., Maratov I.S., Sitnikov P.A. Cellulose, 2017, vol. 24, no. 5, pp. 2153–2162, DOI: 10.1007/s10570-017-1256-3.

21. Torlopov M.A., Mikhaylov V.I., Udoratina E.V., Aleshina L.A., Prusskii A.I., Tsvetkov N.V., Krivoshapkin P.V. Cel-lulose, 2017, vol. 25, no. 2, pp. 1031–1046, DOI: 10.1007/s10570-017-1624-z.

22. Yahya M., Lee H.V., Hamid S.B.A. BioResources, 2015, vol. 10, no. 4, pp. 7627–7639, DOI: 10.15376/biores.10.4.7627-7639.

23. Chen Y.W., Lee H.V., Hamid S.B.A. J. Nano Res., 2016, vol. 41, pp. 96–109, DOI: 10.4028/www.scientific.net/JNanoR.41.96.

24. Man Z., Muhammad N., Sarwono A., Bustam M.A., Kumar M.V., Rafiq S. J. Polym. Environ., 2011, vol. 19, no. 3, pp. 726–731. DOI: 10.1007/s10924-011-0323-3.

25. Miao J., Yu Y., Jiang Z., Zhang L. Cellulose, 2016, vol. 23, no. 2, pp. 1209–1219, DOI: 10.1007/s10570-016-0864-7.

26. Zhang J., Wu J., Yu J., Zhang X., He J., Zhang J. Mater. Chem. Front., 2017, vol. 1, no. 7, pp. 1273–1290, DOI: 10.1039/C6QM00348F.

27. Hirota M., Furihata K., Saito T., Kawada T., Isogai A. Angew. Chem. Int. Ed., 2010, vol. 49, no. 42, pp. 7670–7672, DOI: 10.1002/anie.201003848.

28. Hirota M., Tamura N., Saito T., Isogai A. Cellulose, 2010, vol. 17, no. 2, pp. 279–288, DOI: 10.1007/s10570-009-9381-2.

29. Montanari S., Roumani M., Heux L., Vignon M.R. Macromolecules, 2005, vol. 38, no. 5, pp. 1665–1671, DOI: 10.1021/ma048396c.

30. Peyre J., Pääkkӧnen T., Reza M., Kontturi E. Green Chem., 2015, vol. 17, pp. 808–811, DOI: 10.1039/C4GC02001D.

31. Surov O.V., Voronova M.I., Rubleva N.V., Kuzmicheva L.A., Nikitin D., Choukourov A., Titov V.A., Zakharov A.G. Cellulose, 2018, vol. 25, no. 9, pp. 5035–5048, DOI: 10.1007/s10570-018-1910-4.

32. Revol. J.-F., Bradford H., Giasson J., Marchessault R.H., Gray D.G. Int. J. Biol. Macromol., 1992, vol. 14, no. 3, pp. 170–172, DOI: 10.1016/S0141-8130(05)80008-X.

33. Viet D., Beck-Candanedo S., Gray D.G. Cellulose, 2007, no. 14, pp. 109–113, DOI: 10.1007/s10570-006-9093-9.

34. Beck S., Bouchard J., Berry R. Biomacromolecules, 2012, no. 13, pp. 1486–1494, DOI: 10.1021/bm300191k.

35. Okura H., Wada M., Serizawa T. Chem. Lett., 2014, vol. 43, pp. 601–603, DOI: 10.1246/cl.131181.

36. Siqueira G., Fraschini C., Bras J., Dufresne A., Prud’homme R., Laborie M.-P. European Polymer Journal, 2011, vol. 47, pp. 2216–2220, DOI: 10.1016/j.eurpolymj.2011.09.014.

37. Bruckner J.R., Kuhnhold A., Honorato-Rios C., Schilling T., Lagerwall J.P.F. Langmuir, 2016, vol. 32, pp. 9854–9862, DOI: 10.1021/acs.langmuir.6b02647.

38. Berg O., Capadona J.R., Weder C. Biomacromolecules, 2007, no. 8, pp. 1353–1357, DOI: 10.1021/bm061104q.

39. Cheung C.C.Y., Giese M., Kelly J.A, Hamad W.Y., MacLachlan M.J. ACS Macro Lett., 2013, no. 2, pp. 1016–1020, DOI: 10.1021/mz400464d.

40. Thygesen A., Oddershede J., Lilholt H., Thomsen A.B., Stahl K. Cellulose, 2005, vol. 12, no. 6, pp. 563–576, DOI: 10.1007/s10570-005-9001-8.

41. Elazzouzi-Hafraoui S., Nishiyama Y., Putaux J.L., Heux L., Dubreuil F., Rochas C. Biomacromolecules, 2008, vol. 9, no. 1, pp. 57–65, DOI: 10.1021/bm700769p.

42. French A.D. Cellulose, 2014, vol. 21, no. 2, pp. 885–896, DOI: 10.1007/s10570-013-0030-4.

43. Beck S., Bouchard J., Berry R. Biomacromolecules, 2012, vol. 13, pp. 1486−1494, DOI: 10.1021/bm300191k.

44. Boluk Y., Danumah C. J. Nanopart Res., 2014, vol. 16, pp. 2174–2179, DOI:10.1007/s11051-013-2174-4.

45. Brinkmann A., Chen M., Couillard M., Jakubek Z.J., Leng T., Johnston L.J. Langmuir, 2016, vol. 32, no. 24, pp. 6105−6114, DOI: 10.1021/acs.langmuir.6b01376.

46. Beuguel Q., Tavares J.R., Carreau P.J., Heuzey M.-C. Journal of Colloid and Interface Science, 2018, vol. 516, pp. 23–33, DOI:10.1016/j.jcis.2018.01.035.

Downloads

Additional Files

Published

Issue

Section

License

This work is licensed under a Creative Commons Attribution 4.0 International License.

The authors, which are published in this journal, agree to the following conditions:

1. Authors retain the copyright to the work and transfer to the journal the right of the first publication along with the work, at the same time licensing it under the terms of the Creative Commons Attribution License, which allows others to distribute this work with the obligatory indication of the authorship of this work and a link to the original publication in this journal .

2. The authors retain the right to enter into separate, additional contractual agreements for the non-exclusive distribution of the version of the work published by this journal (for example, to place it in the university depository or to publish it in a book), with reference to the original publication in this journal.

3. Authors are allowed to post their work on the Internet (for example, in a university repository or on their personal website) before and during the review process of this journal, as this may lead to a productive discussion, as well as more links to this published work.